ANSI/TIA-568-C testing ST to ST (Duplex Singlemode) DTX-SFM2

This article will describe the steps required to successfully certify a singlemode ST to ST duplex fiber link in accordance with ANSI/TIA-568-C using the DTX-SFM2 fiber adapters. ANSI/TIA-568-C requires the user to follow Method A.1 (also known as 1 Jumper) which ensures that the connectors at each end of the link are measured and negative loss readings are avoided.

If you have a CertiFiber Pro, click here.

You can also watch Adrian Young of the Fluke Networks Technical Assistance Center explain this on YouTube.

Items required in addition to a DTX CableAnalyzer:

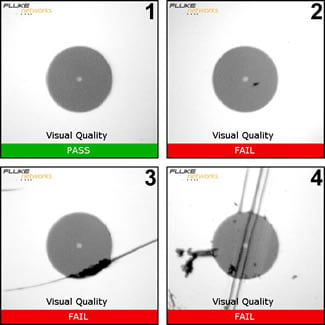

Cleaning is critical. It is the single most reason for ending up with negative loss values. You cannot clean without some means of visually inspecting the end face. This can be anything from a simple Fiber Viewer to a Video Scope such as the FiberInspector Mini shown above. If you have no inspection device, you cannot proceed. Let's define what is acceptable and not acceptable.

|

|

The Test Reference Cords (TRCs) are critical to a successful measurement. Your singlemode TRCs loss should not exceed 0.20 dB at each end. The singlemode TRCs shipped from Fluke Networks;

NFK3-DPLX-ST Duplex SM 9 µm TRC for ST Adapter, Set of 2

have a mated loss better than 0.20 dB at each hardened end face. And yes, you must inspect and clean these TRCs every time you use them - even new ones out of the bag. We'll show you how to check your TRCs for 0.20 dB loss later on in this article.

Where did Fluke Networks get that 0.20 dB requirement?

ANSI/TIA-568-C does not specify a maximum loss requirement for TRCs. However, ISO/IEC 14763-3 does and that's where the 0.10 dB for multimode and 0.20 dB for singlemode comes from.

In this example, we're going to test a 100 m (328 ft) duplex 9/125 µm singlemode fiber link with ST connectors at each end to ANSI/TIA-568-C.

Setting up the DTX CableAnalyzer

- With the fiber modules inserted into the DTX CableAnalyzer, power up the main and remote units.

Sources will need at least five minutes to stabilize, longer in colder or hotter environments.

- Replace the SC Adapters on the main and remote units with the optional ST Adapters.

- Rotate the dial on the DTX CableAnalyzer to SETUP.

- Select Fiber Loss and press ENTER.

- Change the Test Limit to TIA-568-C Singlemode ISP.

You will see two limits for singlemode, one is ISP (Inside Plant) and one is OSP (Outside Plant). The ISP has a fiber loss of 1.0 dB/km and the OSP has a fiber loss of 0.5 dB/km. Choose the one that is appropriate.

- Change the Fiber Type to the cable you are testing.

This setting changes the Refractive Index (n) value. The DTX uses n to calculate the length of the fiber. You can manually enter the n values in Tab 3 of the Setup. If you cannot find your cable in the DTX Cable Library, look to the cable vendor's website for their datasheet. Since the TIA-568-C Singlemode ISP limit is calculated based on length, it is important to get this value right.

- The Number of Adapters is going to be 2.

This is always the number of adapters per fiber strand added after the reference has been set.

- Set the Connector Type to ST.

This will not affect the outcome of the result. It only affects the help screens.

- Set the Test Method to 1 Jumper.

- Clean AND inspect the TRCs.

- Connect the main and remote units together as shown below.

Mandrels must NOT be used.

- Rotate the dial to SPECIAL FUNCTIONS.

- With Set Reference selected, press ENTER then TEST.

- You will then be presented with the results of the Reference.

For 9/125 µm it should be better than -8.00 dBm where -7.50 dBm is better than -8.00 dBm.

These values reflect the cleanliness of the Ports and TRCs. The fact that your reference values are better than the minimum stated above does not mean they are good/clean. In the next few steps, we'll see how good/clean your TRCs really are.

- Press F2 OK.

- You can enter the length of your TRCs here. It does not affect the outcome of the test, but will be displayed on the test report.

- Press F2 OK when done.

- Remove the ST connectors from the Input Ports and put the dust caps back on them.

Never disconnect from the Output Ports. Doing so invalidates the reference you just set.

- Insert one of the ST to ST TRC's into the Input Port on the main unit.

- Insert the other ST to ST TRC into the Input Port on the remote unit.

- You are now ready to test the fiber link, but before you do, let's check out your TRCs. To do this, connect the main and remote units using a singlemode rated ST to ST adapter as shown below.

- Rotate the dial to AUTOTEST and press TEST.

- SAVE the test result so you have evidence of a good Set Reference.

- To view the result, press ENTER. IGNORE the test limit. We're looking to make sure the loss is no greater than 0.25 dB at 1310 nm and 1550 nm. (The extra 0.05 dB is to take into account the uncertainty of the adapter used above for the TRC verification)

This is the fiber connected to the Input Port of the main unit and it looks good.

- Press EXIT and with Loss (Main

Remote) highlighted, press ENTER.

Remote) highlighted, press ENTER.

This is the fiber connected to the Output Port of the main unit. Again, the losses look good.

If the losses here were more than 0.25 dB, then you would want to inspect, clean and redo the Set Reference again.

Can't get anywhere near 0.25 dB? They look ok under the FiberInspector? Your patch cords may not be ISO/IEC 14763-3 TRC rated. Please check with the supplier. Most cords come with the test results in the bag.

Tips:

If you are using the DTX where the temperature is not typical, run the TEST repeatedly with 1 minute intervals to see if the result changes. If it does, you will need to let the sources stabilize and repeat the Set Reference process again.

This procedure is likely to be new to the technician. Have them try this in the office before leaving for the installation.

- Disconnect the main and remote units.

Place dust caps on the remote TRCs if it is more than a short walk to the other end. According to the EPA, dust in an office can be anything from 2.5 µm to 10 µm so protecting the end faces is critical.

- Connect the TRCs to the link you're testing.

- Press TEST.

The DTX CableAnalyzer will calculate the test limit (optical loss budget) for you. Changing the number of adapters/splices will of course increase the test limit. Be sure the Number of Adapters is set correctly.

How often should I Set Reference?

The quick answer is; every time you begin to test a series of fiber links. It is critical to continually inspect the TRCs.