Case Study 3 - Return Loss Fails on DTX CableAnalyzer due to water in cable

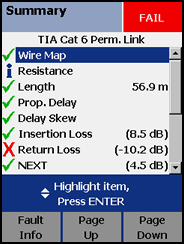

| You can also click here to see a video of Adrian Young from our Technical Assistance Center walking you through these steps. In this case study, the installer was failing Return Loss when certifying a number of category 6 permanent links. With the DTX CableAnalyzer, it is possible to discover why these links were failing. After the AUTOTEST, the installer was presented with the following DTX CableAnalyzer test result.

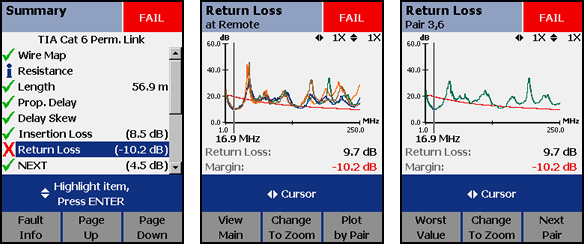

Step 1 Find out which pair combination of Return Loss is causing the FAIL.

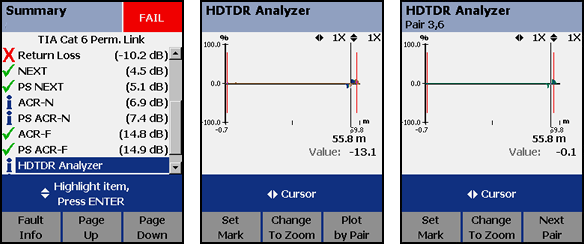

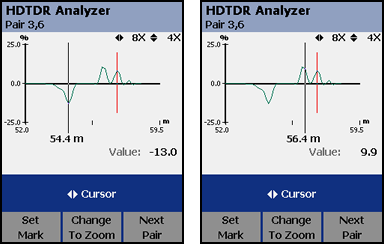

Here we see that Pair 3,6 is the worst pair, although they all appear to be failing about the same - that's a clue. Whenever you see a Return Loss trace that fails at the lower frequencies, it's probably a cable issue. And when all four pairs fail at the lower frequencies and follow each other, as in this example, it's a sign of water/moisture in the cable. Do not confuse moisture with too much lubricant. Too much lubricant will cause a different failure. But where in the link is the water? Step 2 Look at the HDTDR Analyzer trace for this failing pair.

Step 3

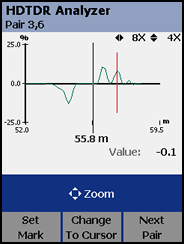

At 54.4 m, you see a value of -13.0. This means that the impedance of the cable has changed by 13%. If the cable before 54.4 m was 100 Ohms, it means the cable now has an impedance of 87 Ohms. The cable remains at 87 Ohms until you reach the next peek where the value is 9.9. Assumnig the cable was 87 Ohms until this point, the cable then becomes 95.6 Ohms. The final peek brings it back to 100 Ohms. |