WHITE PAPER

Category 8 Cable's Role in 25G & 40G DC Ethernet

Download PDF

CATEGORY 8 CABLE WILL PLAY A MAJOR ROLE IN 25G & 40G DATA CENTER ETHERNET

“How the TIA and IEC committees created new standards for Category 8 cable testing devices”

By the end of 2016, several cabling manufacturers are expected to release their initial Category 8 cable products. Representing the next generation of twisted pair cabling, Category 8 supports bandwidths of up to 2GHz and will be used initially in data centers for 25G and 40Gb Ethernet for distances of up to 30 meters (100 feet).

Additionally, cable testing manufacturers will shortly release new Category 8 field testingdevices, enabling contractors to test and verify the real-world performance of Category 8 cabling, and to obtain the warranty from the cabling manufacturer for the end-user.

“Category 8 will play a major role in data centers and mission-critical environments upgrading to 25/40GBASE-T, says Mark Dearing, Senior Product Manager at Leviton. “Cabling manufacturers are now engineering solutions with additional quality and flexibility to meet these demanding new applications. But even the most advanced infrastructure relies on high-quality installation practices to ensure the network will operate at its best. Proper testing and certification in the field translates to less chance of disruption, downtime, and unforeseen costs in the future.”

This article takes an in-depth look at the new standards for Category 8 cable testers, and how these standards were developed.

On This Page

How it was done

In 2011, TIA first submitted the Project Authorization Request (PAR), the official “Call For Interest” for next-generation cabling (with “cabling” defined as the cable and connector together). This prompted cable manufacturers to begin developing Category 8 prototypes and also prompted the ANSI/TIA and ISO/IEC committees to begin developing new standards for Category 8 cabling and field testing devices.

The TIA and IEC committees are made up of representatives from cable, cabling system, and field testing manufacturers, as well as installers and users of cabling systems. While many of these vendors are market competitors, it benefits them to work together to develop a common set of product standards. This ensures that all Category 8 cabling will offer the same performance levels, regardless of manufacturer, and all Category 8 field testers will certify all Category 8 cabling using agreed performance measurement levels.

The committees developed the standards over several years. The final results are:

- ANSI/TIA-568-C.2-1, an update to the established 568-C.2 standard for balanced twisted-pair cabling, includes requirements for Category 8 cabling and components. (ISO/IEC 11801, the international equivalent of these standards, is also being updated with Class I and Class II cabling parameters.)

- ANSI/TIA 1152A, an update to the 1152 standard for field test instruments used to test balanced twisted-pair cabling, was approved for publication in October 2016, and provides specifications for instruments used to test Category 8 cabling. (IEC 61935-1, the international equivalent of the testing standard, is also being updated.)

Developing the testing standards

It’s important to understand that testing Category 8 cabling is not just a matter of increasing the upper frequency of the testing module. In addition to a higher frequency range, Category 8 cabling requires tighter performance specifications in the tester, and new adapters capable of supporting that performance.

To develop Category 8 field testers, manufacturers and committee members developed new requirements and testing methodologies, including:

- Test fixtures specified up to 2 GHz, for use in laboratory test environments

- An RJ45 reference plug specified to 2 GHz.

- Cable and connector performance requirements

- Products to test

These elements were developed in parallel: while cabling manufacturers were developing Category 8 prototypes, cabling and tester companies were also developing laboratory test fixtures, methodologies, and test plugs, so they would be ready to test the Category 8 prototypes once they became available.

Laboratory test fixtures

To develop a standardized cable tester, the TIA and IEC committees first had to agree on standards for testing Category 8 cabling in a lab environment. This required them to develop test fixtures to connect Category 8 cabling to a Vector Network Analyzer. (The VNA is the “yardstick” against which the final testing device is compared, to ensure the tester gives accurate measurements.)

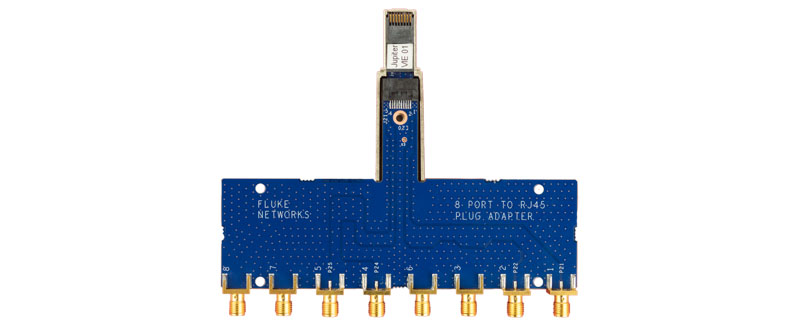

The fixture in Photo #1 connects Category 8 links and components to the VNA. This fixture was developed in conjunction with the TIA and ISO committees, and was created to handle frequencies up to 2 GHz.

The TIA 1183-1 standard for test fixtures was published in January, 2016. Since cable testing manufacturers may create their own version of the lab test fixtures above, the requirements for the fixtures themselves had to be standardized. The goal of this standard is to ensure that all test fixtures created by all cable testing manufacturers will connect to their VNAs in a way that yields accurate and consistent measurements when testing Category 8 cabling samples or RJ45 plugs from different cabling manufacturers.

Standardized RJ45 plugs

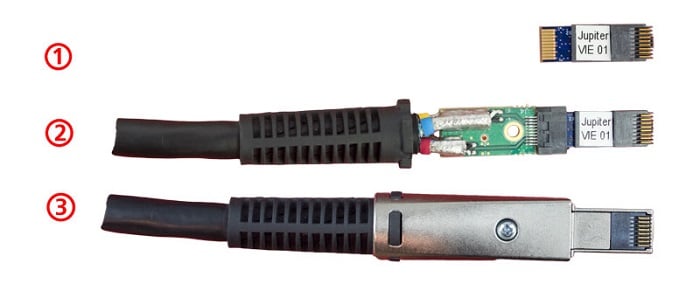

A standardized RJ45 plug is required to perform field measurements. These test plugs have a very tightly-controlled electrical performance, and allow for consistent and accurate measurements of jacks and links from multiple manufacturers. The “Jupiter” RJ45 plug, developed through a joint effort between cabling and cable testing manufacturers, was used as an industry-wide reference for testing Category 8 cabling and components.

Photo #2 shows (1) the original “Jupiter” tip, (2) the “Jupiter” tip installed inside a permanent link adapter (open), and (3) the assembled permanent link adapter, which is a component of the field testing device.

Laboratory test plugs are usually treated with great care, and patch cord plugs may only be inserted a few times. But field tester plugs will be inserted thousands of times, whenever the contractor uses the device for a field test. Therefore, each testing manufacturer must design a version of the plug and jack that will be rugged enough for repeated in-the-field use.

Cable and connector performance requirements

The TIA and IEC standards for Category 8 cabling and connectors had to be finalized to a certain degree, so the testing manufacturers would know which performance metrics to measure in the Category 8 cabling tests. Once the standards were finalized, testing manufacturers were able to accurately test Category 8 cabling prototypes using those metrics, which aided them in developing their final testing products.

In the past year, cabling manufacturers have provided Category 8 prototype samples to testing manufacturers, allowing them to test those samples against the TIA and IEC cabling and connector performance metrics using their VNAs. This crucial step has allowed testing manufacturers to develop handheld devices to accurately test Category 8 cabling in the field.

Final approval

As a “final step” before product release, testing manufacturers submit their Category 8 field testers to the cabling manufacturers for approval. The cabling manufacturers test their Category 8 cabling, first with a field tester, then with a VNA, and compare the tests to ensure that both devices get the exact same results. This proves the field tester can accurately measure Category 8 cabling according to the same performance requirements as a laboratory VNA, allowing the cabling manufacturers to confidently provide warranties for installations certified with these testers.

Certain performance requirements (i.e. transverse conversion loss, resistance unbalance between pairs) have been specified for the first time in Category 8 cabling standards. While these tests are required for cabling and components, they are considered optional tests for installed cabling, due to their complexity. Contractors aren’t required to perform them when certifying Category 8 cabling for the warranty. But if contractors have a Category 8 tester that can test to these requirements, it’s highly recommended that they include these tests. A full range of tests will provide better peace of mind for their clients that the installed Category 8 cabling is working properly, and can handle the client’s applications.

By creating these standards, we’ve helped to ensure these products will work as intended in their “real world” applications, regardless of who manufactures them.

The success of any standards project is largely due to close collaboration among the committee members involved, and to the cooperation of the cabling and cable testing manufacturers they represent. Our mutual collaboration has produced a solid platform of standards, cabling products and field test solutions. We’ve gone through this journey together and are rapidly approaching our destination with a successful launch of Category 8.

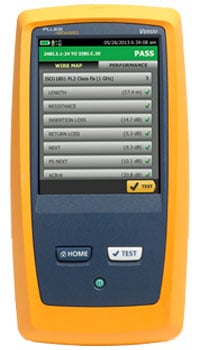

DSX CableAnalyzer™ Series – Accelerates every step of the copper certification process.

The DSX CableAnalyzer Series includes the DSX-8000 which supports certification of all twisted pair standards and the DSX-5000 which can certify up to Cat 6A / FA. The DSX-8000 is the first true Cat 8 field tester with:

- The first Permanent Link and Channel adapters with a full 2 GHz range.

- The first tester to be endorsed by a Cat 8 cabling manufacturer.

- The first tester independently verified to meet the ANSI/TIA-1152-A Level 2G requirements for measurement accuracy required for Cat 8 testers.

- The first tester (along with the DSX-5000) to test screen continuity along the path of the cabling as required for Level 2G testers.

The DSX CableAnalyzers™ reduce the cost of Cat 5 through Cat 8 certification by two-thirds and features the industry's fastest test times (Cat 6A eight seconds) while meeting TIA Level 2G and IEC Level VI – the most stringent accuracy requirements. The DSX integrates with LinkWare™ Live to let you manage jobs and testers from any smart device over Wi-Fi. The future-ready design supports modules for fiber testing (loss, OTDR and inspection). Troubleshoot faults faster with the Taptive™ user interface which graphically displays the source of failures including crosstalk, return loss and shield faults. Analyze test results and create professional test reports using LinkWare™ reporting software.

More information at: www.flukenetworks.com/versiv