Industrial Ethernet Cable Problems - MICE

February 13, 2020 / General, 101 learning, Installation and testing, Upgrading and troubleshooting, Best Practices

Industrial Ethernet is very sensitive to delays caused by dropped or damaged data frames (sometimes called packets). Just a few dropped or damaged packets can cause a machine to shut down. These problems are often intermittent and can be caused by harsh industrial environments.

To solve network related shut-downs, Controls Engineers and Industrial Electricians often replace cables or run bypass cables without knowing if the cable is truly defective or assume a poor cable is good because it passed a continuity test. The toughest problems are intermittent and not easily reproducible, so you don’t really know if the problem was solved.

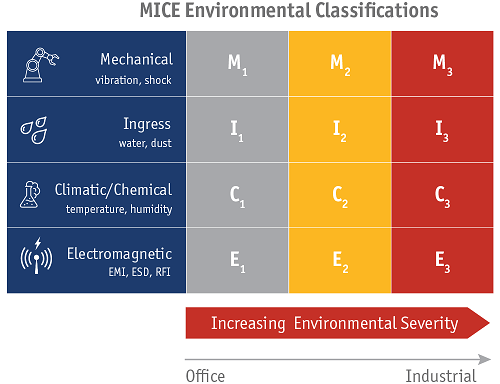

Standards organizations recognized a need to address the harsh environment that can cause intermittent network problems by creating ANSI/TIA-1105-A and ISO 11801:3. They both refer to “MICE” where M is mechanical (flex, vibration), I is Ingress (moisture), C is Climatic (temperature), E is Electromagnetic (noise). MICE standards apply to cabling supporting EtherNet/IP, ProfiNET, EtherCAT, Modbus-TCP and other industrial protocols.

Poor connections can cause intermittent packet loss

The impact of M, I and C levels 2 and 3 can cause Industrial Ethernet cables to experience intermittent continuity problems caused by flexing, vibration, corrosion due to moisture, and temperature changes causing contraction and expansion. Intermittent continuity problems that shut down machines are difficult to find because they appear to be solid connections most of the time. Continuity testers will indicate a pass because they only find open connections not poor connections.

How to determine if an Industrial Ethernet cable has poor connection

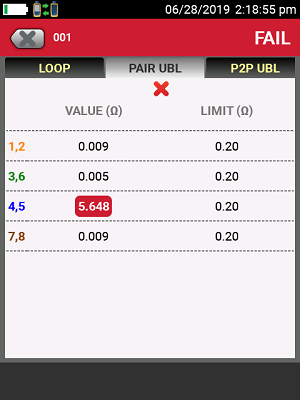

It’s possible to find a poor connection in a two-or four-pair cable using a cable tester that has the ability to measure the resistance of each individual wire with measurement resolution of 0.005 Ω or better. If one wire has significantly higher resistance that the other 7 (or 3), that wire has a poor connection that is likely to become intermittent and cause packet loss and eventually fail completely.

The DSX-5000 and 8000 CableAnalyzer’s DC Resistance Unbalance function easily finds and displays these unbalanced connections.

In the example below, the DSX-5000 identified that the difference between the resistance of wire 4 and wire 5 is greater than 5 ohms which is the result of a poor connection.

Electro-magnetic Interference (EMI) can cause intermittent packet loss

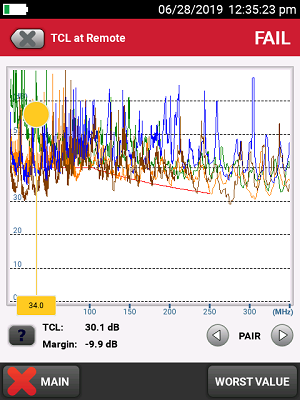

Industrial premises have Variable Frequency Drives (VFD), large motors, magnetic contactors, arc welding equipment and other high-power devices that emit electrostatic, magnetic and radio frequency noise. If only one bit in an ethernet packet is damaged by EMI, a frame error will be created that causes the entire packet to be rejected by a device. If several packets are damaged in a row, a machine could shut down.

Industrial Ethernet cables are supposed to be balanced so that any EMI passing across the cable does not disrupt the low voltage (typically +/-2.5 volt) signals that make up an Ethernet packet. Some cables have excessive unbalance making the cable susceptible to EMI. Unbalance can be caused by installation damage, poor workmanship or materials, or environmental factors (MICE). In some cases, customers use a cable rated for E1 (data room or office environment) in an E3 zone (close to VFDs and other powerful EMI sources). Shielded cables reduce EMI susceptibility, but not all cables are shielded and sometimes shields do not cover the whole cable.

How to determine if an Industrial Ethernet cable is susceptible to EMI

DSX-5000 and 8000 CableAnalyzers address the ‘E’ in MICE with special unbalance measurement functions that determine susceptibility to electro-magnetic fields. These measurements are called Transverse Conversion Loss (TCL) and Equal Level Transverse Conversion Transfer Loss (ELTCTL), and are covered in MICE standards (TIA-1005-A and ISO 11801:3). Test limits to MICE standards can be chosen to match the ‘E’ level of the zone the cable is in; E1 for data rooms or office environments, E3 for zones close to VFDs or other powerful EMI sources, and E2 for cable runs between E1 and E3 zones. Higher E values have tighter balance requirements to reject more packet-damaging EMI.

Please refer to the links below for details on tests to identify MICE problems.

https://www.flukenetworks.com/knowledge-base/dsx-cableanalyzer-series/dc-contact-resistance-issues

https://www.flukenetworks.com/knowledge-base/dsx-cableanalyzer-series/tcl-transverse-conversion-loss-dsx-cableanalyzer

Please visit the link below for information on models, M12X an M12D adapters and other product capabilities.