DATASHEET

FI-3000 / FI2-7300 FiberInspector™ Ultra Camera

Download PDF

Overview

The FI-3000 FiberInspector™ Ultra is the industry's most complete fiber inspection solution. It's the only inspection camera that supports single fiber or MPO; automated or instant manual inspection and works with the Versiv™ Cabling Certification System, LinkWare™ or your smartphone. Get an instant view of the fiber endface using the Live View feature. Then use the simple gesture-based interface to zoom in fiber or perform an optional automated PASS/FAIL analysis in seconds. Its rugged, ergonomic design makes it comfortable even when inspecting hundreds of bulkheads and cables. Choose from two user interface and reporting methods. First, the iOS/Android app allows you to inspect your MPO installation using your phone and easily share your inspection results via text or even social media. Second, pair the FiberInspector with Versiv™ Cabling Certification System using its user interface and industry-leading LinkWare™ reporting system. With Versiv and LinkWare you can test copper, fiber loss, OTDR and inspection and combine the results into one complete report.

The FiberInspector™ Ultra is available in two models:

- FI-3000 FiberInspector™ Ultra – works with both the Versiv™ Cabling Certification System and mobile devices.

- FI2-7300 FiberInspector™ Ultra Kit – includes the FI-3000 camera and Versiv 2 mainframe.

On This Page

- Eliminate the #1 Cause of Fiber Failure

- Grab the Most Complete, Efficient Inspection Solution

- Live View with AutoFocus and AutoCentering for Instant Real Time Visibility

- Detailed Reporting

- Integrates with Versiv™ and LinkWare™ for Project Management and Reporting

- Optional Automated Pass/Fail Testing of Endfaces in Seconds

- Lightweight, Ergonomic Design with Holster

- iOS and Android Apps for Simple Data Sharing

- The Complete Solution for Fiber Inspection

- Ordering Information

Eliminate the #1 Cause of Fiber Failure

Endface contamination the leading cause of fiber failures. Dirt and debris cause insertion loss and reflections that inhibit optical transmission and cause havoc with transceivers. Fiber loss and OTDR testing can expose this problem, but in many cases, dirty connections make fiber testing time consuming and inaccurate.

Since dirt can be an issue before, during, or after fiber optic certification testing, and migrate from one end-face to another upon mating, both sides of any connection must always be cleaned and inspected. Further, mating contaminated connectors can cause permanent damage as microscopic debris is crushed between end-faces in physical contact. Even factory terminated patch cords or pigtails must be inspected as protective caps do not keep end-faces clean. Avoiding this common cause of failure starts with inspecting the end-face and eliminating any contamination before insertion into a bulkhead or piece of equipment. Inspection is critical for MPO based fiber installations as dirt and other debris can be easily moved from one fiber end face to another.

Grab the Most Complete, Efficient Inspection Solution

The FI-3000 FiberInspector™ Ultra offers an extensive feature set that makes testing MPO trunks, cassettes, array cables or single fibers easy and efficient. The multiple camera design with autofocus provides a Live View of the entire endface on your Versiv or smartphone instantly – then use simple touchscreen gestures to get a detailed view of endfaces in real time. Touch “TEST”, and in seconds, you'll get an automated PASS/FAIL result compliant with IEC 61300-3-35. Use the industry-leading LinkWare platform to store complete project reports including copper, fiber loss, OTDR and endface images or store results on your phone and share them through text messages or email. The compact, ergonomic design with autofocus makes it comfortable and fast even when you're testing hundreds of cable or ports.

- Total endface visibility with Live View from full trunk to individual endface

- Integrates with Versiv™ Cabling Certification System and LinkWare™ Reporting Software for simple operation and documentation or with mobile phones for testing and sharing

- Optional automated PASS/FAIL results in less than two seconds per fiber

- Multiple Autofocus/Autocentering Camera design for real time imaging

- Rugged, ergonomic design

- Supports one or two rows of 8,12, 16 or single UPC or APC connectors

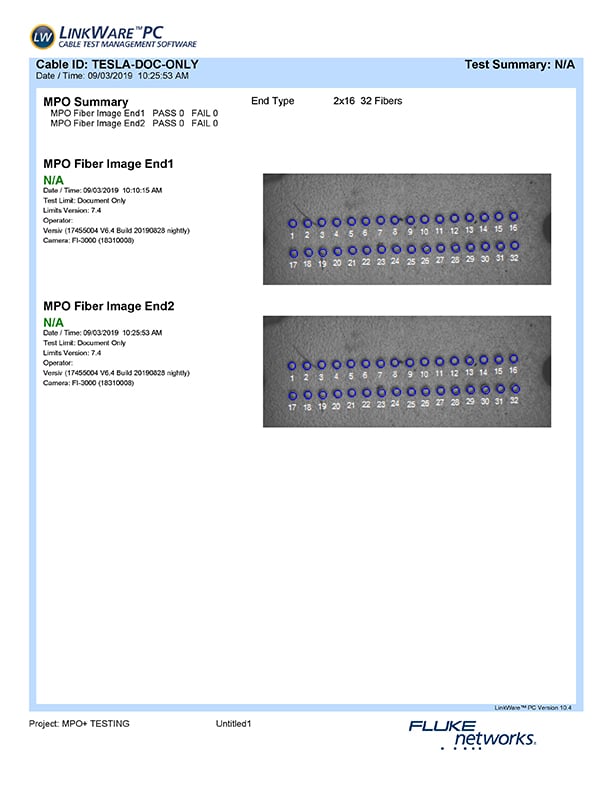

MPO results

Live View with AutoFocus and AutoCentering for Instant Real Time Visibility

Plug the connector into the FI-3000 camera, touch the autofocus button, and the Live View feature delivers a live view of the fiber endface immediately – with no setup or processing time. Dual cameras provide a single, integrated view of the single fiber or entire MPO endface. Use simple gestures to zoom into the portion of interest, pan across the connector or just tap the image of a specific fiber for a detailed view. For documentation, high resolution images of the endface can be stored in the Versiv mainframe, uploaded to LinkWare for reporting or to a mobile phone for easy sharing.

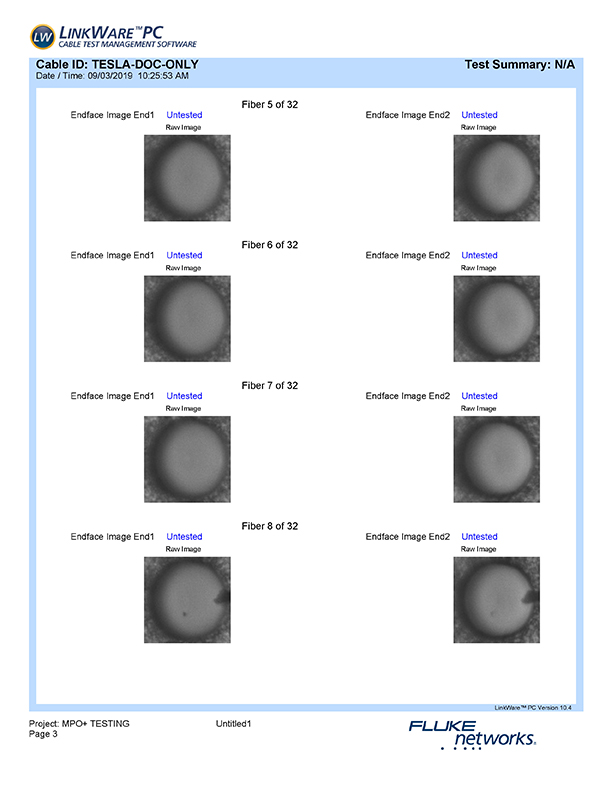

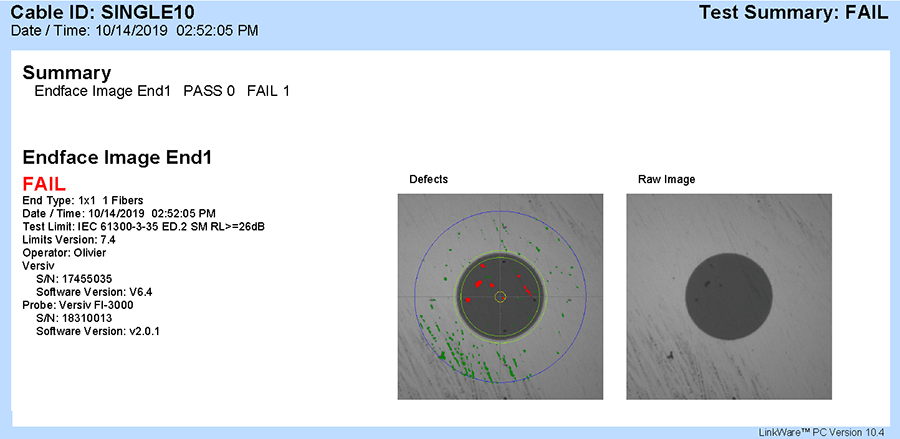

Single fiber results

Detailed Reporting

Single fiber results

MPO results

Summary or detailed reports are available.

Generate detailed PDF reports from your phone or Versiv™ tester. Versiv™ and LinkWare™ also support integrated reports including Tier 1 (Loss) and Tier 2 (OTDR) tests.

Integrates with Versiv™ and LinkWare™ for Project Management and Reporting

For those installing multiple fiber links, MPO trunks, cassettes or array cables as part of a new installation or upgrade, the FI-3000 integrates with any Versiv™ Cabling Certification System for fast, error free project management and reporting. The Versiv brand ProjX™ Management System lets you define each job including the types of cables, identifiers, required tests, and limits. Techs can use the same platform for loss (Tier 1), OTDR (Tier 2) and inspection, reducing training costs and the likelihood of errors. The FI-3000 connects to Versiv via a USB cable.

Versiv features a large, high resolution display that lets you see the results clearly. The gesture-based Taptive™ screen makes it easy to pan across or zoom in and out of the Live View image.

The FI-3000 camera when used with a Versiv mainframe also works with LinkWare – the defacto industry standard for documenting cabling systems. LinkWare lets you combine Tier 1, Tier 2 and inspection results into a single report for full documentation of every link in the system. The cloud-based version, LinkWare Live, makes it easy to track progress of the job from your smartphone or PC and share results with customers.

The FI-3000-NW option provides the user with the ability to test connections using Versiv in secure facilities that do not allow wireless capable devices. This kit has the same configuration as the FI-3000 but with Wi-Fi disabled.

Optional Automated Pass/Fail Testing of Endfaces in Seconds

The FI-3000 camera's optional autotest mode examines all fiber endfaces in the connector, grades them as per industry standard IEC 61300-3-35 and provides an overall PASS or FAIL result in less than two seconds per fiber. The gesture-based user interface makes it easy to switch from the summary to a detailed view.

When an endface fails, the FI-3000 camera shows which fibers failed, and highlights the areas that caused the failure: contamination, pits, chips and scratches. By understanding the cause of the failure, the user can determine the type of cleaning needed or if the connector is damaged beyond repair.

Seamlessly switch from a summary view (left) to an image (center), then use the gesture-based interface to zoom into a view of each individual fiber (right) and pan across the entire connector. Individual fibers are labeled so you know what you’re looking at. Red defects are failures, green are acceptable per the selected standard.

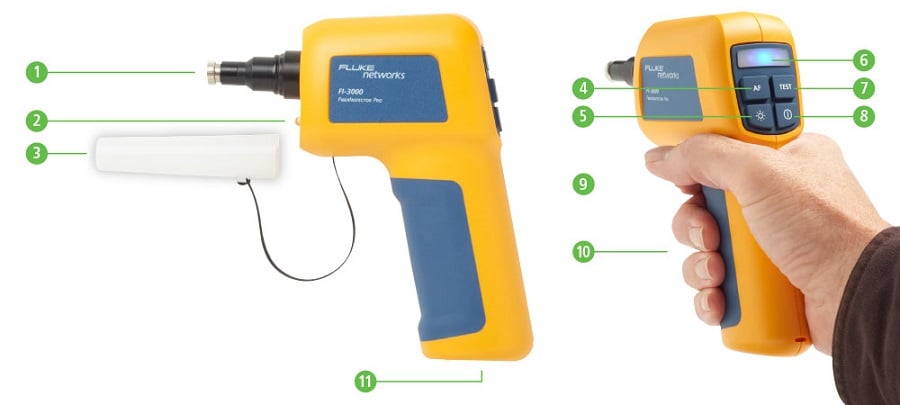

- Interchangeable tips support one or two rows of 8, 12, 16 or single UPC or APC connectors

- PortBright™ illumination for dark and crowded patch panels

- Protective cover with tether

- AutoFocus Control

- PortBright™ on/off

- LED's indicate PASS/FAIL and Wi-Fi connection

- Start an automated test without reaching for your Versiv™ or smartphone

- Auto-off saves battery life

- Ergonomic design comfortable for inspecting cables or ports

- Rugged design for constant field usage

- USB port for charging Li-Ion battery and connecting to Versiv

Lightweight, Ergonomic Design with Holster

The unique design of the FI-3000 camera makes it easy to inspect both bulkheads and trunk cables. The compact and lightweight (326 g / 11.5 oz) design means you can use it all day without fatigue. The built-in PortBright™ illumination makes it easy to find the right port in dense patch panels in dim data centers or dark wiring closets. All FI-3000 models include a holster which provides convenient access to the camera as well as storage for inspection tips and a QuickClean™ cleaner.

iOS and Android Apps for Simple Data Sharing

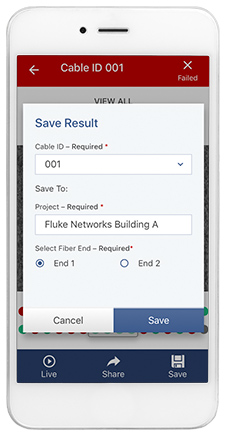

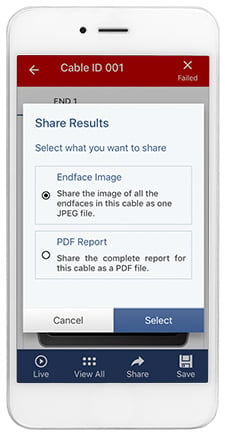

The FI-3000 camera can be connected over Wi-Fi to iOS or Android devices for small jobs or a quick inspection. The FiberInspector app (FI-IN) shows simple PASS/FAIL results, but also gives you complete control over the FI-3000 camera, so you can zoom in or out of each endface and pan across a Live View of the entire endface. FI-IN supports naming and storing of results in the device – or send them as an image or PDF report to others on the team for quick, simple collaboration.

Save results on your phone or share them with others.

The Complete Solution for Fiber Inspection

The FI-3000 FiberInspector Ultra comes with everything you need to test nearly any type of fiber:

- Ergonomic and Rugged FI-3000 Camera with USB and Wi-Fi communications

- MPO tips for 12/24 UPC and 12/24 APC connectors

- Adapter for single fiber

The FI2-7300 FiberInspector Ultra Kit adds a Versiv™ mainframe to the FI-3000

FI-3000 FiberInspector Camera Kit

FI2-7300 FiberInspector(TM) Ultra Camera Versiv Kit

Ordering Information

| FI-3000 Wireless Models, Tips, Adapters, and Accessories | |

|---|---|

| Model | Description |

| FI2-7300 | The FI2-7300 FiberInspector™ Ultra Kit contains: Versiv Mainframe, FI-3000 MPO/Single fiber Camera, Holster, USB-USB C cable to connect the probe to the mainframe, Tip Set (12/24 UPC and 12/24 APC), Single Fiber Adapter for FI-1000 tips, Blank Module to protect the mainframe's rear connector, AC Charger, Shoulder Strap, USB Interface Cable, Versiv Open Source Software CD, Integrated Wi-Fi, Getting Started Guide, Soft Carrying Case. |

| FI2-7300-NW | Same configuration as the FI2-7300 with integrated Wi-Fi disabled. |

| FI-3000 | FI-3000 FiberInspector Ultra Camera, with Tip Set (12/24 UPC and 12/24 APC), Single Fiber Adapter for FI-1000 tips, AC charger, Getting Started Guide, Holster, Soft Carrying Case |

| FI-3000-NW | Same configuration as the FI-3000 with integrated Wi-Fi disabled |

| FI-3000TP-UMPO12F | MPO 12 or 24 UPC tip |

| FI-3000TP-AMPO12F | MPO 12 or 24 APC tip |

| FI-3000TP-UMPO16F | MPO 16 or 32 UPC tip |

| FI-3000-1000ADP | Adapter to connect FI-1000 tips to FI-3000 probe |

| FI-3000-500ADP | FI-3000-500ADPAdapter to connect FI-500 tips to FI-3000 probe |

| FI1000-1.25-UTIP | 1.25 universal patch cord |

| FI1000-LC-PCTIP | LC patch cords |

| FI1000-1.25APC-TIP | 1.25 APC universal patch cord |

| FI1000-LCAPC-PTIP | LC APC universal patch cord |

| FI1000-2.5-UTIP | 2.5 universal patch cord |

| FI1000-2.5APC-UTIP | APC universal patch cord |

| FI1000-EXND-LC-TIP | Extended LC Bulkhead |

| FI1000-LCAPC-BTIP | LC/APC lens bulkhead |

| FI1000-SCFC-tip | SC and FC Bulkhead |

| FI1000-SCAPC-Tip | SC/APC bulkhead cord end faces |

| FI1000-ST-TIP | ST bulkhead video probe tip |

| FI-3000-Holster | Holster for the FI-3000 probe |

| QC-MPO-12/24-1P | QuickClean Cleaner for MPO 12/24 Fiber, Single Pack |

| QC-MPO-12/24-5P | QuickClean Cleaner for MPO 12/24 Fiber, Pack of 5 cleaners |

| QC-MPO-16/32-1P | QuickClean Cleaner for MPO 16/32 Fiber, Single Pack |

| QC-MPO-16/32-5P | QuickClean Cleaner for MPO 16/32 Fiber, Pack of 5 cleaners |

| QuickClean-1.25-1P | QuickClean Cleaner 2.5 mm Fiber, Single Pack |

| QuickClean-1.25-5P | QuickClean Cleaner 2.5 mm Fiber, Pack of 5 cleaners |

| QuickClean-2.5-1P | QuickClean Cleaner 2.5 mm Fiber, Single Pack |

| QuickClean-2.5-5P | QuickClean Cleaner 2.5 mm Fiber, Pack of 5 cleaners |

| Gold Support Models | |

|---|---|

| Model | Description |

| GLD-FI-7300 | 1 year Gold Support for the FI2-7300 kit |

| GLD3-FI-7300 | 3 year Gold Support for the FI2-7300 kit |

| GLD-FI-3000 | 1 year Gold Support for the FI-3000 camera |

| GLD3-FI-3000 | 3 year Gold Support for the FI-3000 camera |

| Environmental | |

|---|---|

| Temperature range |

Operating: -10° C to +45° C (+14° F to +113° F) Storage: -10° C to +60° C (+14° F to +140° F) |

| Humidity range |

Operating: 0 % to 95 % (32° F to 95° F, 0° C to 35° C) RH non-condensing Storage: 0 % to 95 % (95° F to 113° F, 35° C to 45° C) RH non-condensing |

| Altitude |

Operating: 4,000 m (3,200 m with AC adapter) Storage: 12,000 m |

| Vibration | 2 g, 5 Hz to 500 Hz |

| Shock | 1 meter drop test |

| Safety | IEC 61010-1: Pollution Degree 2 |

| EMC |

IEC 61326-1: Controlled Electromagnetic Environment; IEC 61326-2-1 CISPR 11: Group 2, Class A USA (FCC): 47 CFR 15 Intentional Radiators: This device complies with part 15 of the FCC Rules. |

| Endtype Support | Single Fiber and MPO: 1x8 (8 fibers), 1x12 (8, 10, or 12 fibers), 1x16 (16 fibers), 2x12 (16, 20, or 24 fibers), 2x16 (32 fibers) |

| Test Limits |

IEC 61300-3-35 ED. 2 MM IEC 61300-3-35 ED. 2 SM APC Document Only |

| Camera type | 5 Megapixel 1/4-inch CMOS sensor |

| Field of view | 610 µm x 460 µm |

| Resolution | 1 µm |

| Light source | LED, >100,000 hr life |

| Endface illumination | Coaxial blue LED |

| Port illumination | White LED |

| Battery Type | Lithium-ion; 10.8 hour life |

| Power Adapter |

Input: 100 to 240 VAC ±10 %, 50/60 Hz Output: 15 VDC, 2 A maximum Class II |

| Wireless Transmission* |

Output power: <100 mW Frequency ranges: 2.4 GHz (2412 MHz to 2462 MHz) |

| Dimensions |

6.625 in x 5.375 in x 2.125 in (168 mm x 137 mm x 54 mm) (with no dust cap or adapter tip) Length with dust cap: 7.5 in (191 mm) |

| Weight | 11.5 oz (326 gm) (with dust cap and no adapter tip) |

|

* For more information, go to www.flukenetworks.com/manuals and search for “Radio Frequency Data for Class A” |

|