Overview OTDR - Optical Time Domain Reflectometer

An Optical Time Domain Reflectometer (OTDR) is a device that tests the integrity of a fiber cable and is used for the building, certifying, maintaining, and troubleshooting fiber optic systems. Hand-held OTDRs build a virtual image of the fiber optic cable to determine the condition and performance capability of the fiber cable. These tools can also test components along the cable path like connection points, bends, or splices to analyze the cable’s capability from start to finish.

On This Page

- What is OTDR Fiber Testing?

- Using an OTDR to Certify New Links

- Detecting Problems Using an OTDR

- Documents and Resources

- Related Products

OTDR Working Principle

The process of running these tests requires the OTDR tool to input a light pulse into one end of a fiber cable. The results are based on the reflected signal that returns to the same OTDR port. Some of the light transmitted through the cable will scatter and some will be reflected and returned to the OTDR. This returned scatter and reflections are measured to gather useful information about the cable, such as loss and distances to connectors or faults. This is measured by recording the time it takes for signals to return to the OTDR.

OTDR Testing Parameters

With so many different uses for OTDR testing, setting the correct OTDR parameters can ensure the tests you run and measurements you get are accurate. For some tests, using the auto-test function may be enough to get you accurate results, but other may require you to manually set the OTDR testing parameters based on fiber cable length, type of cable, and complexity of your system. These OTDR parameters will adjust the pulse width, averaging time, dead zones, and the distance range for your given fiber run to offer the most accurate results.

Using an OTDR to Certify New Links

Most customers are familiar with Basic Certification - sometimes known as Tier 1 fiber certification – which measures attenuation (insertion loss), length and polarity. This test ensures that the fiber link exhibits less loss than the maximum allowable loss budget for the immediate application. Simple Light Source/ Power Meters or more automated Optical Loss Test Sets can perform this function.

Viewing trace results is simplified with advanced features such as pinch and zoom

Extended or Tier 2 fiber certification supplements Tier 1 testing with the addition of an Optical Time Domain Reflectometer (OTDR) from end to end. An OTDR trace is a graphical signature of a fiber's attenuation along its length which provides insight into the performance of the link components (cable, connectors and splices) and the quality of the installation by examining non-uniformities in the OTDR trace. More advanced units can provide easy to understand Event Maps and loss values for individual components as well as the link. An OTDR trace helps characterize individual events that can often be invisible when conducting only loss/length (tier 1) testing. Only with a complete fiber certification can installers have a complete picture of the fiber installation and network owners have proof of a quality installation. This fiber test certifies that the workmanship and quality of the installation meets the design and warranty specifications for current and future applications.

Bi-Directional Testing with an OTDR

Industry standards and most manufacturers’ warranties require TIer 2 testing to be done bi-directionally, that is, from both ends of the link.; It's also the only way to know the actual overall loss for a link because measuring the loss of fiber connectors and splices, as well as overall link loss, depends on the test direction. Testing a fiber link in one direction can give you different results than testing the same fiber link in the opposite direction. Averaging the results from both directions is required to achieve an accurate measurement.

Because of the significant time and cost involved in testing from both ends, technicians often try to save as much time as possible by testing all links from one end before moving to the other end. Unfortunately, this method does not work. To accurately test a fiber link in both directions, the launch and tail cords must remain in their initial measurement positions (even the standards say so) during both tests. But that is simply not possible if you test all the links from one end before moving to the other.

Bi-directional testing on an OTDR can test fiber cables in both directions with a loop

To solve this dilemma, you can test two fibers at the same time and use a loop to connect the two fibers together. This allows the two fibers of a duplex link to be tested in one shot without moving the OTDR to the far end. OTDRs like Fluke Networks OptiFiber® Pro OTDR Family of tools feature “SmartLoop” Technology that checks for the presence of the launch, loop and tail fiber when testing a duplex fiber link.

With SmartLoop, technicians can deploy multiple loops at the far end and perform a set of bidirectional tests without ever having to leave the near end--cutting test time by at least 50%.

OTDR Trace Analysis

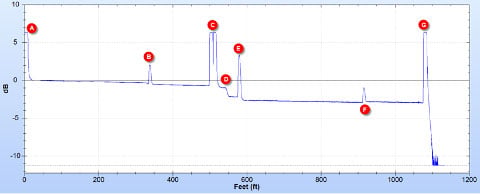

Typical OTDR trace, showing length, a gradual decline in light strength, and events (A) OTDR connector – note the large reflectance makes it impossible to characterize the loss in the first connector. In this case a launch fiber of about 300 ft. is being used. This allows the OTDR to characterize the first connector of the link under test (B). (C) shows two connectors that are too close together for the OTDR to properly characterize the loss in each. (D) is a loss event with no reflectance, likely a bad splice or APC connector. (E) shows a typical UPC connector with reflectance and loss. (F) depicts a connector with reflectance where the signal after the connector is stronger than before, often called a “gainer”. This is indicative of connecting fiber types with different backscatter properties. (G) is the end of the fiber. Note the strong reflection makes it impossible to determine if there is a connector there and its performance.

Detecting Problems Using an OTDR

OTDRs are also used for troubleshooting fiber plant performance. An OTDR maps the cabling and can illustrate termination quality and location of faults that may hinder network performance. An OTDR allows discovery of issues along the length of a channel that may affect long term reliability. OTDRs characterize features such as attenuation uniformity and attenuation rate, segment length, location and insertion loss of connectors and splices, and other events such as sharp bends that may have been incurred during cable installation or afterwards. Newer technologies, such as 100BASE-DR, also set limits on reflectance for each connector in the link, which can be verified only with an OTDR.

When selecting the right OTDR, network engineers should make sure the tool has certain functionality, such as loss-length certification, channel/event map view, power meter capabilities, an easy-to-use interface, and smart-remote options. In addition, the OTDR needs to provide a reliable means to document the results. Features that make the OTDR easy to operate such as automated setup and Event Map are essential for users who aren’t OTDR experts but need to locate problems fast.

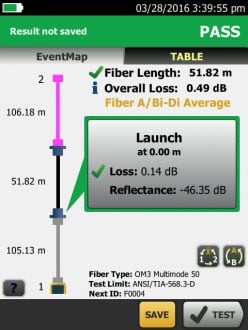

OptiFiber Pro® OTDR Offers Testing and Troubleshooting capabilities.

Tools such as the award winning OptiFiber® Pro OTDR provide the ultimate testing and troubleshooting solution to ensure the health of your most critical network cabling. With the OptiFiber Pro OTDR, network engineers have the in-house capability to perform inspection, verification, certification, troubleshooting, and documentation of fiber cabling in a single, easy-to-use OTDR tool.

Keep reading

- • White Paper: Troubleshooting Fiber

- • Choosing the Right OTDR for your Datacenter

- • OLTS & OTDR: A Complete Testing Strategy

- • OTDR: Your Ultimate Troubleshooter

- • OTDR Knowledge Base Articles