Clean Cords are Reliable Cords

May 24, 2017 / General, 101 learning, Installation and testing, Upgrading and troubleshooting, Best Practices

Or, what a minor obsession with reliability looks like.

We don’t get a lot of complaints about our product quality, so when we do, it gets our interest. After recently receiving a field complaint that a user’s OTDR launch packs were degrading rapidly, specifically the reflectance on the LC/APC connectors, our team devised a simple test to assess the problem. Two 160 meter launch packs were randomly selected from production stock. An actuator was setup that would allow automated mating and un-mating of the SC/APC connector pair. Connector attenuation and reflectance using an OTDR were measured at the beginning of the test and after every 25 mates. Any “outlier” measured after a 25 mate cycle warranted cleaning of the connector endface.

Cleaning was not done after every mating because the actuator mechanics prevents easy access, so the test was considered less than ideal (i.e., what Fluke would recommend for cleaning and inspecting). However, measurements were done in a clean environment. Any measurement change observed after a 25 mating cycle would necessitate inspection, cleaning, then test continuation. The goal of the testing was to observe when and how connector attenuation and reflectance would increase after 500 mates, 1000 mates, and beyond.

OTDR setup

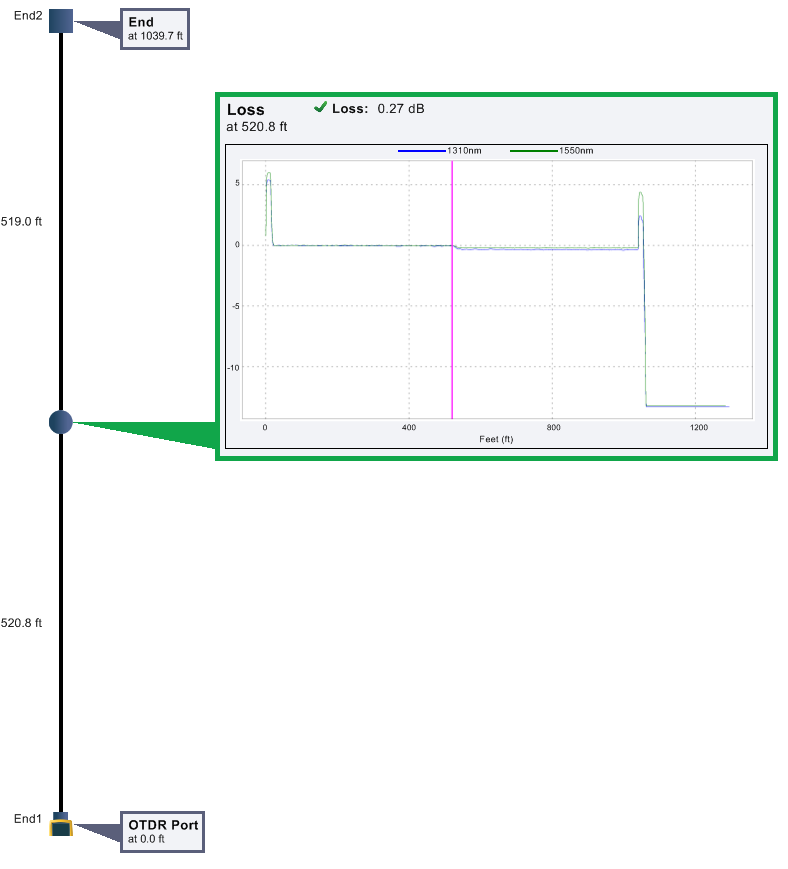

A single-mode OTDR was used. The OTDR trace in Figure 1 shows where the measurements were made and how the trace appeared initially or after cleaning.

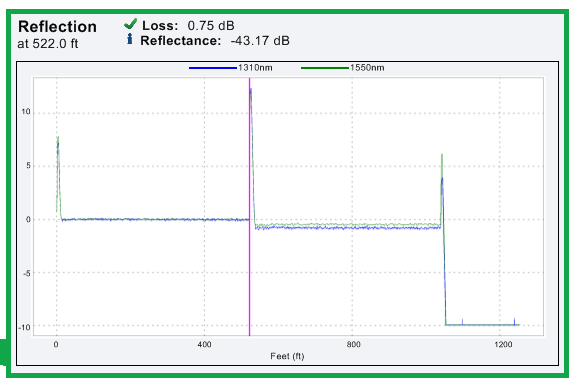

Figure 2 shows how the OTDR trace appeared when debris was found at the connector end face. Notice the increase in the pulse height at the cursor location found at the center of the trace.

Connector attenuation data

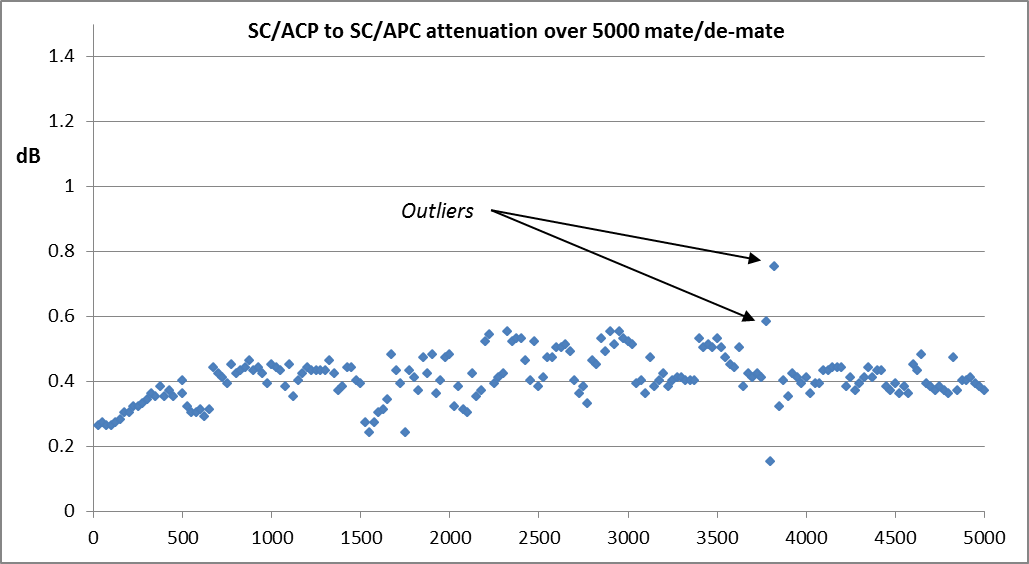

Without apparent degradation in optical performance (attenuation) between mated SC/APC connectors, testing was concluded after 5,000 mates and de-mates. The connector end face was cleaned a total of 7 times and only after attenuation or reflectance degraded (which accounts for the outliers). See a summary of the attenuation data below and the raw data in Figure 3.

After 500 insertions, the average attenuation was 0.32 dB.

After 500 to 1000 insertions, the average attenuation was 0.39 dB.

After 1000 to 2000 insertions, the average attenuation was 0.40 dB.

After 2000 to 3000 insertions, the average attenuation reached a peak of 0.45 dB.

After 3000 to 4000 insertions, the average attenuation dropped a small amount to 0.43 dB.

Finally, after 4000 to 5000 insertions, the average attenuation dropped further to 0.40 dB.

Connector reflectance data

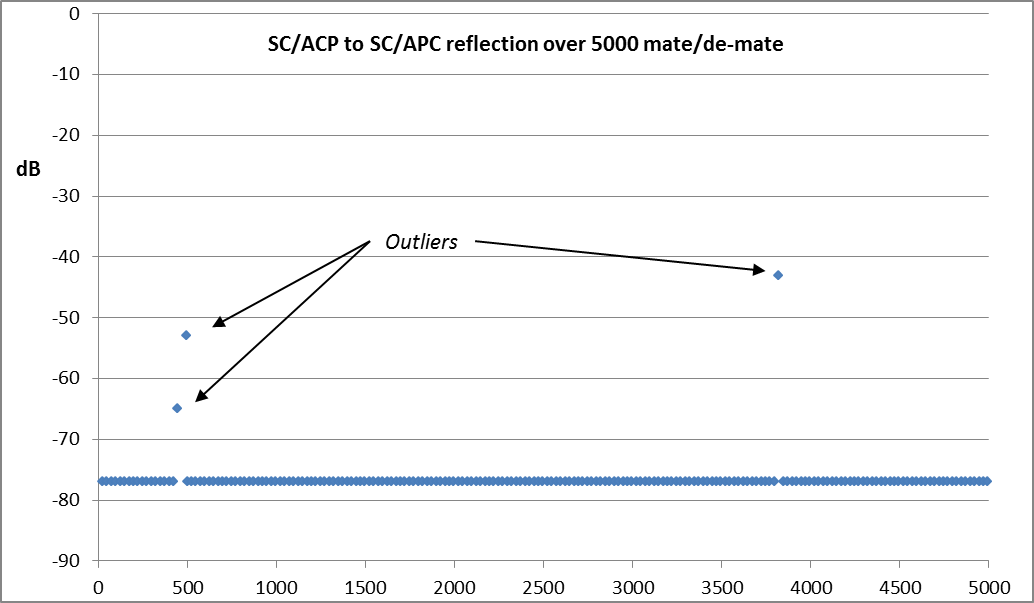

The reflectance measured with an OTDR, except for the outliers caused by debris, remained very stable at -77 dB. See Figure 4 below.

Summary

We have demonstrated, with a sample of one, what is possible from an SC/APC connector pair after repeated matings/de-matings, if done in a clean environment. For any outlier that appeared, cleaning restored the next measurement to the measurement prior to the outlier data point. Testing stopped after 5000 matings which took several days.

Since the sample size was “one”, by no means do these measurements represent all connector performance. However, the measurements on one sample do provide some insight into what you might expect from your connectors if they are cared for. So, protect your investment and keep your connectors clean. Your launch cords will thank you.